Blog

Stock Valves

STOCK VALVE INVENTORY LEVELS ARE NOW AVAILABLE TO VIEW IN REAL-TIME ON OUR WEBSITE HERE: Stock Valves

6 Applications of Throttling Valves

Throttling valves are specialized valves that facilities can use to regulate/control flow. They are typically globe-style designs, allowing for the control of flow through the valve sealing surfaces. Single seated, globe-type valves provide for uniform wear on the seat and disc. Throttling valves are used in various applications, including feedwater by-pass applications, blowdown applications, and more.

Throttling Valve Applications

Some of the most common applications for throttling valves include:

Blowdown Applications

When generating steam to produce power, blowdown is an important step that involves modulating the flow rate of water flashing to steam. It is not uncommon for power plants to utilize standard globe valves for blowdown applications. However, the harsh conditions found in this type of setting, particularly in continuous blowdown and intermittent blowdown, generally exceed the capabilities of these valves.

Continuous blowdown valves remove dissolved solids from the boiler feedwater. The valve must be able to handle continuous flashing service 24/7 and then shut tight when required. Intermittent blowdown valves are used to rapidly blowdown the HP/IP drum to control swell during firing, in duct burners, and when ramping up. Traditionally this is a standard globe or metal seated ball valve.

Due to the flashing service, this is a great application for a Conval throttling valve. In regions where plants have frequent starts and stops, they could use their intermittent blowdowns 2-3 times per day 200+ days a year. Operators can use throttling valves to keep the facilities running cost-effectively and efficiently.

Total Dissolved Solids Steam Drum Applications

When suspended solids begin to build up within a boiler, it negatively impacts heat transfer. As these solids begin to dissolve, boiler water may start foaming and become incorporated into the steam. Throttling valves help prevent these issues by controlling the flow of water as it is periodically discharged from the boiler. These regular discharges ultimately reduce the overall levels of total dissolved solids within the boiler water.

Power Plant Quick Start/Warm Up Applications

When starting a cold Heat Recovery Steam Generator (HRSG), the drums will have no pressure. To fill the drums, the plant will use their HP/IP/LP level valves, which are normally cage-guided control valves. This application typically requires a full-ported valve with an equal percentage trim. This type of cage struggles to handle the high pressure drop of a cold start when there is no pressure on the outlet of the valve. An alternative is to install a parallel Conval throttling valve as a sacrificial valve to take the high pressure drop as the drum fills.

Feedwater By-Pass Applications

Throttling valves play an important role in extending the lifespan of the cage trim within feedwater regulator valves. Without the use of a throttling valve, feedwater impacts the cage trim at a high velocity whenever the regulator valve opens. Over time, this repeated exposure to high-velocity water can damage the cage trim. To avoid this, throttling valves can bypass the initial burst of feedwater until the regulator valve opens. After it has opened to approximately 20%, the regulator valve can take over without the risk of exposure to high-velocity water.

Boiler Feedpump Warm-Up

Prior to starting up the boiler feedpumps, throttling valves are utilized to flow hot water through the warming loop on the pump in order to maintain the case temperature. This reduces the thermal shock during start-up.

Hydro-Cracker Effluent Sampling Applications

Valves in this type of application have an SS316 yoke and are composed of SS347. These valves are often made from non-standard materials, including Ultimet, Nitronic 50, and Nitronic 60.

Throttling Valves From Conval, Inc.

Since 1967, Conval, Inc. has been manufacturing industry-leading forged steel valves. We are dedicated to creating durable, high-performance valves that can operate dependably even in high-pressure, high-temperature applications. Our throttling valves offer repeatable flow control, with the best shutoff in the industry. To find out how we can meet your throttling valve needs, contact us today.

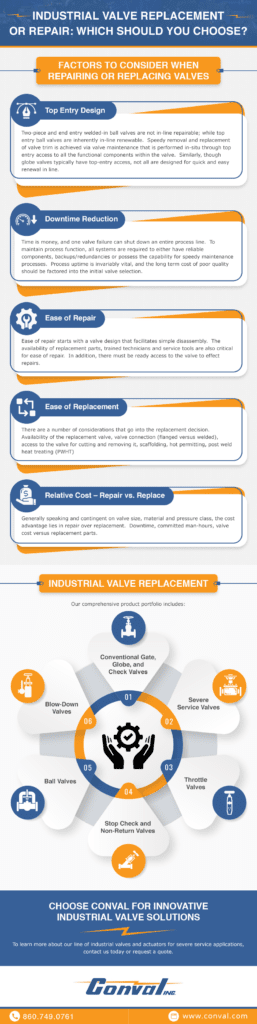

Industrial Valve Replacement or Repair: Which Should You Choose?

Thousands of small-diameter ball, check, globe, and gate valves are installed in industrial plants to facilitate a variety of power, process, mixing, and refining applications. They are critical for ensuring reliable control over the temperature, velocity, pressure, and flow of a wide range of media. When one of these valves fails, many organizations opt for valve replacement rather than repair. The choice between industrial valve repair and industrial valve replacement depends on a number of considerations.

Below are some of the factors to take into account when determining whether to repair or replace a valve.

Factors To Consider When Repairing or Replacing Valves

When considering whether you should repair or replace your industrial valve, the experts at Conval recommend considering the following factors:

- Top Entry Design

Two-piece and end entry welded-in ball valves are not in-line repairable; while top entry ball valves are inherently in-line renewable. Speedy removal and replacement of valve trim is achieved via valve maintenance that is performed in-situ through top entry access to all the functional components within the valve. Similarly, though globe valves typically have top-entry access, not all are designed for quick and easy renewal in line. - Downtime Reduction

Time is money, and one valve failure can shut down an entire process line. To maintain process function, all systems are required to either have reliable components, backups/redundancies or possess the capability for speedy maintenance processes. Process uptime is invariably vital, and the long term cost of poor quality should be factored into the initial valve selection. - Ease of Repair

Ease of repair starts with a valve design that facilitates simple disassembly. The availability of replacement parts, trained technicians and service tools are also critical for ease of repair. In addition, there must be ready access to the valve to effect repairs. - Ease of Replacement

There are a number of considerations that go into the replacement decision. Availability of the replacement valve, valve connection (flanged versus welded), access to the valve for cutting and removing it, scaffolding, hot permitting, post weld heat treating (PWHT) - Relative Cost – Repair vs. Replace

Generally speaking and contingent on valve size, material and pressure class, the cost advantage lies in repair over replacement. Downtime, committed man-hours, valve cost versus replacement parts.

Industrial Valve Replacement

At Conval, we can replace globe, gate, check, ball, and angle valves in sizes between 1/4″ and 6”. Whether you are in need of a check valve for your industrial process fluids or a dependable severe service globe valve, we have the knowledge and equipment necessary to help you keep your valves in prime operating condition. We offer expert consultation and valve replacements for even the most rigorous applications. Our comprehensive product portfolio includes:

- Conventional Gate, Globe, and Check Valves

- Severe Service Valves

- Throttle Valves

- Stop Check and Non-Return Valves

- Ball Valves

- Blow-Down Valves

Our unique in-line renewability makes our products a step above the rest. Conval’s Clampseal® and Camseal® in-line renewable valves feature a leak-proof bonnet that allows easy access for inspection and maintenance without having to cut the valve out of the line. Unlike more traditional methods for ball and globe valve replacements, our Clampseal and Camseal valves allow you to quickly replace critical valve components in under an hour.

Choose Conval for Innovative Industrial Valve Solutions

At Conval, we offer a range of valves and valve replacements services to meet your needs. Our products are engineered for durability, long life cycle, high performance, and optimal safety. We aim to become the recognized leader in on-time and quick delivery of severe-service flow control products, exceeding customer expectations for safety, life-cycle value, and process up-time.

Whether conditions favor repair or replacement, Conval is the choice. Our robust designs are proven in severe service applications for long service life, and we manufacture here in the U.S.A. Each valve type is designed with ease of repair in mind, and our patented top entry, cartridge sealing Camseal, high pressure/temperature MSBV, is first in its class, offering simple, quick maintenance. For either replacement or repair, Conval design features ensure minimal downtime for our customers. To learn more about our line of industrial valves and actuators for severe service applications, contact us today or request a quote.

Conval Clampseal® Globe Body Styles

Global valves come in a variety of body styles to suit different applications. Below, the valve experts at Conval discuss the three main globe valve body styles available to help existing and potential customers understand the differences between them.

Y-Pattern vs. T-Pattern vs. Angle Pattern

Conval currently produces Clampseals® in the three preferred styles of forged globe valves with a few additional variations. The three styles are referred to as “Y”, “T” and “Angle” patterns. The names are based on the valve’s configuration.

Y-Pattern

The Y-pattern design is our best-selling globe valve. It is named for the Y shape of the body forging. The main advantage of the Y globe valve is that its flow rate (Cv) is greater than the traditional T globe valve. The Y configuration may also facilitate installation in tight envelopes and allow the use of a smaller valve, thereby saving money for the customer.

T-Pattern

The T-pattern is likely the oldest globe valve design since it was developed by the ancient Phoenicians. It is named for the valve’s 90° stem versus pipeline orientation (i.e., the stem is at a right angle to the pipeline). The advantage of having the stem at 90° to the valve is that the seismic properties (i.e., the ability to withstand a seismic event) are enhanced. A T-pattern globe valve is also better at supporting an actuator atop the yoke since all the weight and stresses do not cause bending moments on the yoke arms and bonnet threads.

Angle Pattern

The Angle pattern design incorporates a 90-degree turn in the flow path. It can be highly advantageous in a piping system design since it eliminates the need for an elbow in the pipe run, which reduces the number of parts and welds required. Additionally, some Angle pattern valves have a higher Cvthan comparable Y-pattern globes. This style of globe valve is typically used in throttling and blowdown applications.

Conval: Your Expert & Partner for High-Quality Globe Valves

Conval is a premier designer and manufacturer of severe service gate, globe, check, ball, and bellow seal valves in Enfield, CT., USA. We offer Y-pattern, T-pattern, and Angle pattern globe valves suitable for isolating and controlling flow in a range of piping applications. While most of our sales are in Y globe valves, some customers prefer T-globes or specify them when actuation is required. We also maintain capabilities for angle globe valves for specialized applications (e.g., continuous blowdown).

To learn more about our valve offerings and how they can benefit your operations, contact us today.

Choosing the Right Valve: Gate Valves vs. Ball Valves vs. Globe Valves

Gate, ball, and globe valves are used extensively in isolation (on/off) and throttling (flow control) applications across residential, commercial, municipal, and industrial settings. Selecting the right valve for the intended use is oftentimes critical, as the results of misapplication can have catastrophic impacts in terms of safety, budget, and the environment.

Numerous variables require careful consideration when choosing the right valve for a given application, but generally, the selection process seeks to match valve functionality with its intended purpose. For basic on/off applications, the selection process can often be relatively simple, but the process becomes increasingly complicated as valve function becomes more complex and applications increase in severity.

Application Variables

An array of conditions exist that may affect the choice of a valve for a given application, including:

- System pressure

- Temperature

- Flow conditions (Cv/flow rate)

- Media (liquid, gas, steam)

- Media properties (corrosive fluids, lethal chemicals, costly fluids, etc.)

The intended purpose for the valve is also a key variable. For instance, the selection process for the valve used to flow water into a municipal building differs significantly from that for the valve used to control high-pressure steam in a power plant, or a valve used in a highly corrosive chemical application. Consider the following during valve selection:

- Is the valve intended to isolate flow?

- Is it intended to control flow?

- Is it required to be multi-functional (e.g. throttle and isolate, isolate and prevent backflow)?

- What degree of seat tightness (sealing integrity) is required for the application?

Function Variables

Valves are designed to perform specific functions, including:

- Isolation (on/off)

- Controlling flow (throttling)

- Preventing reverse flow

- Diverting flow

- Overpressure protection

Most isolation and throttling valves will consist of a valve body that houses the sealing surfaces (seats) and provides end connections for mating pipes or vessels. The body will have a mating bonnet (cover) and a yoke to house the stem drive mechanism, though in some designs, the bonnet and yoke are incorporated into one piece. Valves are supplied with an obturator designed to be placed in the flow path (driven by the stem) for sealing or regulating flow, such as a:

- Gate/wedge

- Globe/disc

- Ball

Valves may be automated utilizing electric, pneumatic, or hydraulic actuators to effect valve stroking, both for sealing and for regulating flow.

Gate Valves

Gate valves are utilized to isolate flow. They use an obturator inserted into the flow path via a drive mechanism, employing a threaded stem and a handwheel designed to provide a minimum torque required to seal the obturator against the adjoining seats. In addition to manual operation, a host of options exist featuring electric, pneumatic, or hydraulic actuation to perform the closing function.

Gate valves are often referred to as multi-turn valves, as the handwheel must be repeatedly turned 360 degrees as the valve is opened or closed. They are provided in reduced and full port configurations, and in wedge gate and parallel slide designs. While they seal well, Wedge gate valves are susceptible to thermal binding in applications exceeding 800°F. Above this temperature, parallel slide gate valves are recommended. Gate valves 3 inches and under are typically supplied with forged bodies, while larger diameter valves are typically supplied with cast bodies. A number of manufacturers also supply large diameter, high pressure forged gates.

Low-pressure (ASME 150-600#), cast steel gate valves are readily available through valve distribution organizations, and are used in a wide variety of general purpose applications across industries, including process applications, pipelines, water distribution, and steam distribution.

Ball Valves

Ball valves are generally used to isolate flow. They employ a ball as an obturator with a flow path through the ball matching the bore diameter at the seating surfaces. Available in reduced, full, and “V” port (for controlling flow) configurations, ball valves are supplied in a wide variety of styles, including one piece, two piece, three piece, top entry, and welded. Ball types include a floating ball design (a ball held in place by the seats and stem) or a trunnion-mounted design which mechanically holds the ball in place at its top and bottom.

Considered quarter-turn valves, ball valves go from fully open to fully closed with a 90 degree movement of the handwheel/lever connected to a shaft, which makes them easier to operate and typically less expensive to actuate. A wide range of electric, pneumatic, and hydraulic actuators may be incorporated to automate ball valves.

Low-pressure ball valves are readily available and used in a wide variety of industries and applications, including

pipeline, water distribution, steam distribution, chemical, refineries, and petrochemical. Standard ball valves may be used only for very light throttling, except those intended for control and supplied with a “V” port style ball.

Globe Valves

Globe valves are utilized to isolate flow or to control (throttle) flow in a piping system. They feature a globe or disc obturator driven into the single body seat via a drive mechanism. This mechanism employs a threaded stem and a handwheel that are designed to provide a minimum torque required for sealing.

The single-seated globe valve is capable of both throttling and isolation services. As the valve closes, flow is evenly distributed around the full circumference of the sealing surfaces, resulting in even wear. This is not the case in gate valves or ball valves. The flow path through the globe valve is often referred to as tortuous, as flow must come up (or down) through the single seat. This flow path creates a higher pressure drop and lower Cv compared to gate or ball valves.

Like gate valves, globe valves are multi-turn valves. There are a wide range of options for electric, pneumatic, or hydraulic actuation to perform the closing function. Globe valve designs include y-pattern, T-Pattern, and angle pattern, based on the orientation of the stem to the flow path. Each of these may be used for on/off and throttling services, but the angle-pattern globe is typically utilized where right angles exist in the piping and where higher degrees of throttling are required (i.e., continuous blowdown).

These valves are typically sized for the flow conditions found within their intended critical application. The flow path for Y-pattern valves is less tortuous than in T- and angle-pattern valves, providing for a marginally higher Cv. Y-pattern valves are used extensively in vent and drain applications found in power plants and other similar applications.

Ball Valves vs. Gate and Globe Valves

Valve manufacturers and process owners/users can now design and specify ball valves for non-throttling applications typically reserved for gate and globe valves thanks to the tighter tolerance capabilities of modern CNC machining equipment, as well as advances in the development of extremely hard coating materials and the processes to apply them. The smaller relative footprint and weight of ball valves versus gate and globe valves reduces stresses in piping systems, while quarter-turn stroking facilitates easier operation and reduces automation costs. These factors may also provide longer service life in some severe-service applications. Ball valves can sometimes be more costly than their gate and globe counterparts, but in many instances, these advantages may compensate for the difference.

About Conval

Conval is a premier manufacturer of high-quality forged steel valves used in high-pressure, high-temperature, and severe-service applications. We offer fast and on-time delivery of severe-service flow control products that exceed expectations. Valve solutions from Conval offer numerous benefits to users, including:

- Durability

- Excellent life cycle value

- Easy maintenance

- High performance

- Quality

- Safety

- Reduced plant downtime

- In-line renewability/repairability

To see how long-lasting, severe-service valves from Conval can improve your operation, please don’t hesitate to contact us today.

UPDATE ON CONVAL’S NUCLEAR PROGRAM – NUPIC AUDIT AND ASME RENEWAL SURVEY

The months of April and May saw Conval audited by two separate organizations for the purpose of determining the acceptability and implementation of our nuclear quality assurance program.

On April 26th, the Nuclear Procurement Issues Corporation (NUPIC), an organization made up of domestic and international member utilities, arrived with a team of seven auditors, representing Dominion Energy (2), PG&E, Exelon (2), AEP, and Duke Energy. The results of the audit were positive, and the team exited on Friday April 30th.

On May 11th, representatives from ASME, the National Board and Conval’s Authorized Inspection Agency (OneCIS) began a survey/audit for the purpose of renewing Conval’s N and NPT Certificates of Authorization. The team exited on May 14th, and will make a recommendation to ASME to renew the subject Certificates of Authorization.

Conval remains committed to supporting operating nuclear power plants, as well as those being designed and constructed, with our world class globe, gate, check, ball and bellow seal valves, proudly designed and manufactured in the U.S. Please contact Don Bowers or Kristopher Stevens for additional information, or any questions that you might have.

Types of Check Valves and Their Applications

The purpose of check valves is to prevent backflow within a piping system. Check valves are unidirectional valves that provide unobstructed flow in one direction as long as flow pressure remains constant and protect the piping system against reverse flow. The three main types of check valves we offer are ball, piston, and stop check valves.

Piston Check Valves

Also part of the lift check valve family, piston check valves incorporate a weighted piston (or disc) to prevent backflow. These function in a manner similar to ball check valves, allowing for flow as long as flow pressure remains steady, but applying gravitational closure when flow pressure decreases to a point where it no longer has the force to lift the valve.

The valve bore maintains and guides piston alignment throughout its travel. Depending on flow conditions, piston check valves sometimes include spring assistance to aid in closure. Common cases employing piston check valves include:

- Feed water control in the nuclear industry

- Dump lines

- Make-up water

- Miscellaneous process systems

- N2 systems

- Monitoring and sampling systems

Ball Check Valves

Ball check valves are lift check valves, and use a weighted ball rather than a disc to allow flow and inhibit backflow. Once the cracking pressure is attained, the ball lifts up from its seat, allowing flow to occur. When there is a reduction of flow pressure, it falls back into place to prevent backflow.

Applications of ball check valves include instances where high-pressure and high-velocity flows are critical and backflow may damage upstream components (Applications similar to piston check valves, but more suited to those for more viscous media).

Stop Check Valves

Stop check valves combine the benefits of lift check valves with the positive closure functionality of globe valves. These features allow for the control of flow regardless of direction. The main purpose of stop check valves is to prevent damage to pump or boiler systems upstream of the valve in the piping system. Common case applications of stop check valves include:

- Heat recovery steam

- High-temperature service

- Geothermal service

- High-pressure safety service

- Utilities

- Safety systems

- Shutdown cooling

- Petroleum production and refining

- Hydrocarbon processing

Check Valve FAQ

What are some advantages/disadvantages of check valves?

The primary advantage of a check valve is they prevent reverse flow while typically requiring no external actuation. They also provide a fast-acting solution to preventing backflow. Some disadvantages include the inability to determine the condition of the valve and its status, limitation(s) on its installation configurations, and the possibility of sticking in the open position (not often a problem associated with ball and piston types).

How do you choose the right check valve?

There are several factors to consider when deciding on a check valve for your needs:

- Material Selection: Material used for valve construction must stand up to piping system and media demands associated with the specific type of gas or liquid flowing through the piping system.

- Performance Requirements: Performance considerations include the capability of the valve to handle various temperature and pressure instances.

- Type and Size: Selection of the right check valve includes control considerations, typically related to increased safety in hazardous applications as well as sizing the valve to properly accommodate the piping system’s flow conditions.

- Maintenance: In addition to considering the frequency of maintenance or replacement, operators must also think about the valve’s resistance to clogging, jamming, or otherwise malfunctioning.

- Special Requirements: Check valve selection also includes several special requirements unique to their function, including response time, cracking pressure, normally closed vs. normally open, vertical vs. horizontal mounting, flow direction (upward or downward) and fluid density.

How do you prevent check valves from failing?

One of the disadvantages of check valves is the difficulty of determining the condition of the enclosed valve. Consequently, there are certain measures necessary for recognizing their failure and preventing it. Several indicators that signal failure or potential failure include valve vibration (chattering), measured reverse flow, excessive component wear, audible indications of leakage (water hammer), and leaking. You can prevent failure by:

- Proper sizing

- Routine inspections for cleanliness

- Proper installation

- Replacing valves as needed

Check valves play an important role in controlling flow within high-performance piping systems. Selecting the right check valve provides greater piping system efficiency and improves operational safety.

Conval is a leading global provider of check valves specifically designed to meet the unique needs of our customers. Contact us to learn more about the solutions we offer or request a quote to get started on your next project.

Severe Service Valves

At Conval, we specialize in high-performance valves for demanding applications. For over 50 years in business, our products have found use in a wide range of industries, including chemical processing, mining, oil and gas, and power generation (fossil and nuclear). Our extensive experience, combined with our differentiating technical expertise in valve design, manufacturing, in-depth application knowledge, and long-lasting customer relationships enables us to provide customers with solutions that offer superior product life cycle and performance.

Overview of Severe Service Valves

Valves can be classified into two main categories: general purpose/commodity and severe service. The design, manufacturing and quality considerations for the various applications in each category are incorporated accordingly. General purpose/commodity valves are suitable for standard (i.e., non-severe) applications, where severe service valves are suitable for more demanding applications. Using the right configuration for a particular application is essential since the wrong choice can lead to equipment failure and, consequently, loss of product, potential safety hazards and costly downtime.

Regarding severe service valves, applications typically involve the following conditions:

- Extreme (very high/low) temperatures. Severe service valves withstand use in temperatures below -400° F or above 1,200° F without leaking or failing.

- Excessive or fluctuating pressures. Severe service valves maintain sealing integrity when exposed to high pressures or fluctuating pressure conditions.

- Abrasive or corrosive media. Severe service valves incorporate materials of construction that are not susceptible to damage from abrasive (e.g., solids, sediments, or particulate matter) or corrosive (e.g., strong chemical) media.

When Are Severe Service Valves Needed?

As indicated above, severe service valves are used in applications with extreme temperatures, high pressures, and/or abrasive or corrosive media. They are specially engineered to withstand these conditions without failing. Other situations where severe service valves may be needed include those involving:

- Cryogenic fluids

- Fugitive emissions

- Lethal fluids

- Slurries

- Steam

- Tight closures

In addition to these applications, any company operating a high-risk process would benefit from the additional durability and reliability provided by severe service valves.

Severe Service Valve Industries

Many industries utilize severe service valves to ensure durable and reliable performance in their demanding applications. Some examples of industries that commonly use them include:

- Chemical and petrochemical

- Metal and mineral mining

- Urea manufacturing

- Oil and gas

- Power generation (fossil and nuclear)

- Pulp and paper

Severe Service Valves at Conval

Conval offers a broad selection of valves engineered to suit challenging work environments. They are available in a variety of styles with various features and specifications to suit different applications. Note that all Conval designs can be supplied in standard materials, including ASTM A105, F11, F22, F316, F91, F92 and custom materials such as Monel®, Hastelloy®, Inconel®, duplex and super duplex materials and others as specified by our customers. Conval products can be supplied with all end connection options.

CLAMPSEAL® Globe Valves

CLAMPSEAL globe valves eliminate unnecessary complexity through the use of standardized internals regardless of the valve body style. They deliver the highest degree of versatility and are completely customized to each customer’s requirements. Clampseal Globe valves are available in three body styles: Y, Angle, and T-pattern. Because the design consists of internal parts that are completely interchangeable, spare parts inventories may be kept at lower levels.

These valves are available in standard sizes through 4 inches and ASME pressure classes through 4500#.

Swivldisc® Gate Valves

Swivldisc gate valves excel in high-pressure and high-temperature applications. They are available in a wide variety of end connections and feature a low emissions gate valve design. They achieve perfect alignment using an innovative, flexible disc to deliver a tight seal that isn’t possible with standard wedge gate valves. The simple and effective CLAMPSEAL pressure seal bonnet provides ready access for servicing with no welds to cut or seal rings or gaskets to replace. The body-to-bonnet joint integrity is maintained through countless thermal cycles. The fine finish of the stem and chamber combines with high performance graphite packing to ensure long packing service life.

These valves are available in standard sizes through 4 inches and ASME pressure classes up to intermediate 3500#.

Camseal® Ball Valves

Designed for extremely demanding high-pressure and high-temperature applications, Camseal ball valves ensure zero body, stem seal, and seat leakage. They feature a top entry, single forged body design which facilitates long service life and in-line rebuilding with no welding or stress relieving required. They are available in three metal seating configurations, depending on the needs of your application. The low emissions ball valve design delivers low life cycle costs and is available in a wide selection of end connections.

These valves are available in standard sizes through 4 inches and ASME pressure classes through 4500#.

Steam Whisperjets

Conval’s innovative Whisperjets are designed to provide cavitation-free pressure letdown where processes require large pressure drops. Through a multitude of pressure reduction stages, Whisperjet assemblies create impinging flow patterns that dissipate energy without significant wear to the control surfaces, handling pressure drops safely and affordably. With this product, steam flows through a series of computer-designed pressure reduction stages, assuring extremely long service life. By preventing sonic flow and critical pressure drops from occurring, fluid velocities and sound levels are minimized. Due to their simple design, Whisperjets are a low-cost solution to velocity problems that may be encountered in piping systems. They may be applied in conjunction with a valve or as independent pipeline components.

Whisperjets are available in ASME pressure classes through 4500#.

Clampseal® Check Valves

In applications requiring protection against reverse flow, Clampseal check valves are a versatile solution. They control fluid flow using only two moving parts, ensuring long-term, reliable operation. These valves are available in multiple body sizes and in Angle, T, and Y-patterns as well as in piston, ball, and stop check configurations. Clampseal check valves provide reliable performance through countless pressure cycles. They are easily serviced since the pressure seal bonnet design does not include welds that need to be cut nor any gaskets that require replacing.

These valves are available in standard sizes through 4 inches and ASME pressure classes through 4500#.

Any standard Conval valve can be configured to meet customer specifications. Standard valves are made using a modular design with interchangeable parts, making it simple to alter standard valve designs to meet the unique demands of each application. Our team can help you select the best valve type with customized options for your application.

Conval: High-Performance Valve Solutions for Demanding Applications

Conval is a trusted process industry supplier of innovative severe service valve products. We offer the most customizable high-performance flow control solutions in the market. If you need a product you can rely on to perform in your demanding applications, we’ve got you covered. Our valves can withstand extreme pressures, high and low (cryogenic) temperatures, and abrasive/corrosive media with industry leading product life-cycle and performance. Additionally, they quickly achieve ROI goals as a function of service life and ease of in-line maintenance. To learn more about our valve products and why you should invest in them, contact us today. To get started on your solution, request a quote.

Valves in HRSG Combined Cycle Plants

Users report that Conval valves offer superior performance in HRSG combined cycle plants.

When Heat Recovery Steam Generator (HRSG) combined cycle plants were first designed and built several decades ago, many of the originally-installed actuator/valve packages included lower-quality, foreign made globe, gate and ball valves. Time and experience have now shown that these inferior valves only last 4-5 years or less. By comparison, where Conval’s were specified and installed, typical valve life has been more like 16-20 years. Based on this real-life experience, more HRSG maintenance supervisors and planners are choosing to replace original lower-quality, foreign made valves with new Conval Camseal ball valves, Swivldisc gate valves and Clampseal globe valves. Sometimes these plants already stock Conval valves. If they do not, factory deliveries are good. If the original valves are actuated, Conval can match the footprint of the actuator for easy replacement. Based on users’ experience, Conval valves are being used in such key HRSG combined cycle cations as isolation, vents, drains, and feedwater. By their very nature, these plants frequently cycle up and down, on and off, which is very difficult on any mechanical equipment. Most OEM valves simply cannot perform in these highly demanding circumstances. Plant managers and their staffs are discovering that Conval is the smartest, most economical valve choice from a total life cycle standpoint.

Product Brochures Now Available On-Line

Conval’s family of product literature is now available to download in pdf format.

Click here to view our CLAMPSEAL® CAMSEAL® and other product brochures