Industrial Valve Replacement or Repair: Which Should You Choose? Request a Quote Contact Us

Thousands of small-diameter ball, check, globe, and gate valves are installed in industrial plants to facilitate a variety of power, process, mixing, and refining applications. They are critical for ensuring reliable control over the temperature, velocity, pressure, and flow of a wide range of media. When one of these valves fails, many organizations opt for valve replacement rather than repair. The choice between industrial valve repair and industrial valve replacement depends on a number of considerations.

Below are some of the factors to take into account when determining whether to repair or replace a valve.

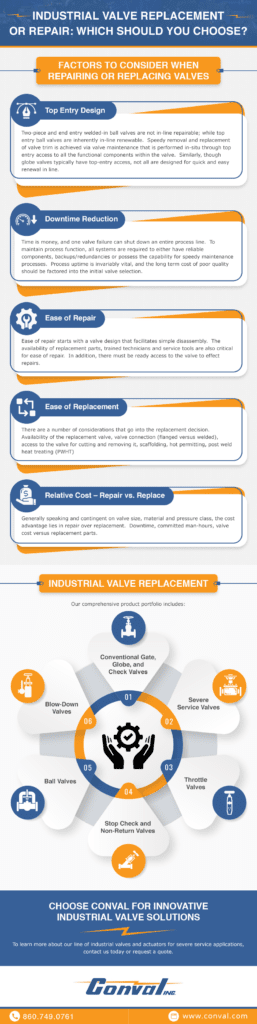

Factors To Consider When Repairing or Replacing Valves

When considering whether you should repair or replace your industrial valve, the experts at Conval recommend considering the following factors:

- Top Entry Design

Two-piece and end entry welded-in ball valves are not in-line repairable; while top entry ball valves are inherently in-line renewable. Speedy removal and replacement of valve trim is achieved via valve maintenance that is performed in-situ through top entry access to all the functional components within the valve. Similarly, though globe valves typically have top-entry access, not all are designed for quick and easy renewal in line. - Downtime Reduction

Time is money, and one valve failure can shut down an entire process line. To maintain process function, all systems are required to either have reliable components, backups/redundancies or possess the capability for speedy maintenance processes. Process uptime is invariably vital, and the long term cost of poor quality should be factored into the initial valve selection. - Ease of Repair

Ease of repair starts with a valve design that facilitates simple disassembly. The availability of replacement parts, trained technicians and service tools are also critical for ease of repair. In addition, there must be ready access to the valve to effect repairs. - Ease of Replacement

There are a number of considerations that go into the replacement decision. Availability of the replacement valve, valve connection (flanged versus welded), access to the valve for cutting and removing it, scaffolding, hot permitting, post weld heat treating (PWHT) - Relative Cost – Repair vs. Replace

Generally speaking and contingent on valve size, material and pressure class, the cost advantage lies in repair over replacement. Downtime, committed man-hours, valve cost versus replacement parts.

Industrial Valve Replacement

At Conval, we can replace globe, gate, check, ball, and angle valves in sizes between 1/4″ and 6”. Whether you are in need of a check valve for your industrial process fluids or a dependable severe service globe valve, we have the knowledge and equipment necessary to help you keep your valves in prime operating condition. We offer expert consultation and valve replacements for even the most rigorous applications. Our comprehensive product portfolio includes:

- Conventional Gate, Globe, and Check Valves

- Severe Service Valves

- Throttle Valves

- Stop Check and Non-Return Valves

- Ball Valves

- Blow-Down Valves

Our unique in-line renewability makes our products a step above the rest. Conval’s Clampseal® and Camseal® in-line renewable valves feature a leak-proof bonnet that allows easy access for inspection and maintenance without having to cut the valve out of the line. Unlike more traditional methods for ball and globe valve replacements, our Clampseal and Camseal valves allow you to quickly replace critical valve components in under an hour.

Choose Conval for Innovative Industrial Valve Solutions

At Conval, we offer a range of valves and valve replacements services to meet your needs. Our products are engineered for durability, long life cycle, high performance, and optimal safety. We aim to become the recognized leader in on-time and quick delivery of severe-service flow control products, exceeding customer expectations for safety, life-cycle value, and process up-time.

Whether conditions favor repair or replacement, Conval is the choice. Our robust designs are proven in severe service applications for long service life, and we manufacture here in the U.S.A. Each valve type is designed with ease of repair in mind, and our patented top entry, cartridge sealing Camseal, high pressure/temperature MSBV, is first in its class, offering simple, quick maintenance. For either replacement or repair, Conval design features ensure minimal downtime for our customers. To learn more about our line of industrial valves and actuators for severe service applications, contact us today or request a quote.